What is aluminium?

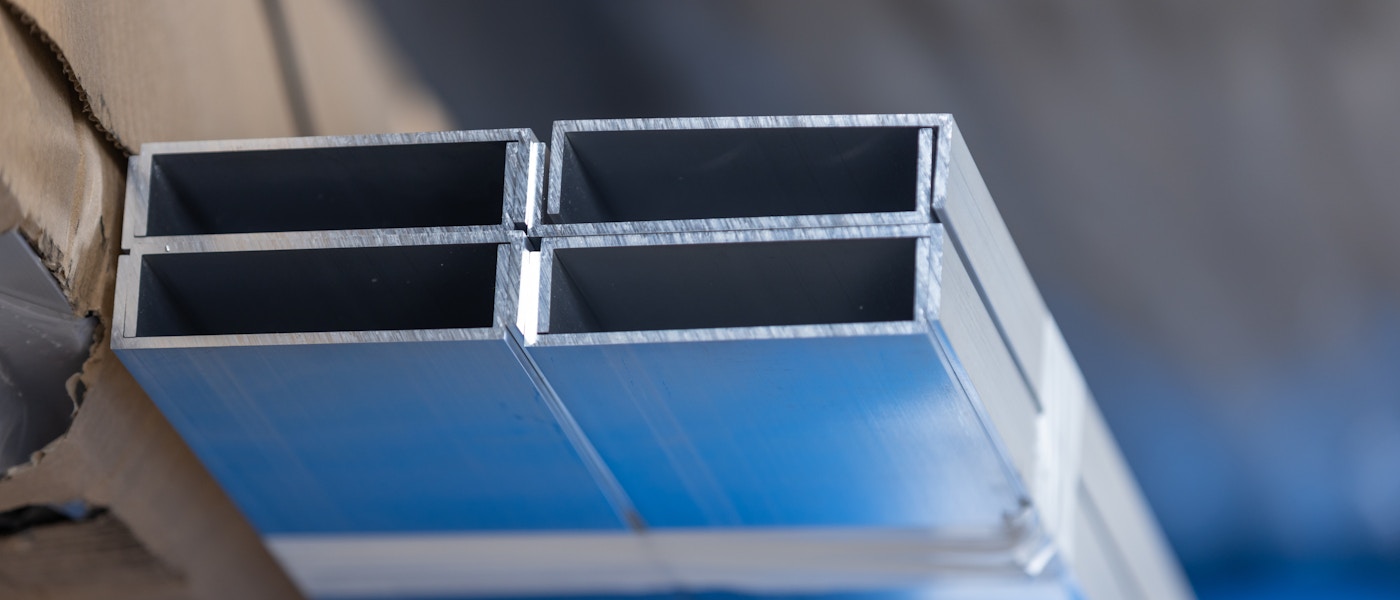

Aluminium is a chemical marvel combining an incredibly vast alloying potential with superb natural strengths and values.

As a substance it has unrivalled versatility that can be adapted for multiple applications throughout all of today’s leading industries, including marine, architectural, building, automotive and aeronautic, to name just some of its multi-use industries.

Aluminium in its raw form is resilient, weather resistant, aesthetically desirable and very easy to machine and fabricate.

It is the most abundant of earth’s natural metals and when mixed with other natural elements such as magnesium and silicon, its potential uses grow almost limitlessly.

This mixing potential creates a vast range of chemical compositions that all have varying properties and practical applications, otherwise known as alloys.

It is aluminium’s alloying potential that sets it apart in the metals market and makes it the number one option for countless suppliers and businesses.

These days, due to its exceptional adaptability, the use of aluminium can be found throughout almost any business, from the biggest architectural endeavours to designing small intricate parts that need pinpoint precision, aluminium in many cases can also be used as a smarter substitute for plastic.

Not only is it one of the easiest materials to work with but it also requires little upkeep and maintenance once installed.

Among its most valued characteristics are that it doesn’t rust or tarnish ensuring a dependable surface shine for many years into the future.

It is this natural eye-catching mirror sheen that makes it absolutely ideal for many of today’s advertising projects and goes hand in hand with another of its desirable attributes, aluminium can also be painted or anodised. Later in this article, we show a brief ‘how-to guide’ on the painting process.

Cutting aluminium

Another advantage of using aluminium angles is that unlike harder metals such as steel, aluminium creates far fewer and “colder” sparks during the cutting process, so for many projects aluminium is a safer metal to use.

This being the case, we would always recommend the required safety precautions are observed such as protective eyewear and gloves at the barest minimum.

Use and benefits of aluminium angles

Aluminium angles can be used in a variety of imaginative and practical ways, some are best applied to large-scale commercial operations, while others find their home in everyday DIY projects. Some uses indeed cross the bridge between both forms of application.

Firstly, let us look at some closer-to-home everyday uses for aluminium angles.

Disguising screw holes

A common issue for any would-be DIYer is the cosmetic appearance of screw holes. Screw holes are of course, unavoidable and not only look bad but can also chip and splinter presenting potential hazards.

Aluminium angles are an ideal solution to cover this area and improve the look while at the same time strengthening the area and reducing potential dangers.

Hiding gaps

Many woods and plastics can often become uneven or shear while being worked, once again creating an unwanted physical appeal and creating possible hazards.

While the go-to solution would often be to sand or plane the area, another perhaps more viable solution is to install aluminium angles to cover any chipped edges and again strengthen a potentially vulnerable pressure point.

Creating a decorative border

Among the most prized advantages of aluminium as a display material are that it doesn’t rust and is easily cleaned.

This, plus its anti-corrosive characteristics make it an ideal metal for use in multiple types of decoration. The ability to use aluminium indoors or outdoors interchangeably is a standout quality unrivalled by other metals.

Cover any rough edges

Aluminium angles can also be relied upon to cover any rough or uneven surfaces that cannot be otherwise smoothed over.

Used correctly, their pristine shine can turn an ugly aesthetic negative into a stunning positive, or at the very least cover the most apparent ugliness.

Grind Bar Fabrication

Aluminium is also found in some less obvious settings, venues such as skate parks and winter sports arenas, for example, have begun to use aluminium throughout their designs.

For these environments, aluminium's stand-out quality is that it doesn’t spark when it contacts other metals, plus it creates a protective outer barrier for any material underneath that would otherwise quickly tarnish.

One important potential downside that must be considered is that aluminium angles add bulk to a project so all preliminary measurements should cater for this.

Painting aluminium angles

If the natural silver shine isn't the desired look, then aluminium can also be painted.

The watchword here is ‘can’. Aluminium is a non-ferrous metal so it can be tricky to paint when compared to some other metals, nonetheless, it is entirely doable.

We have a guide to the various methods of finishing aluminium: https://www.rightonblackburns....

Required materials and tools

Wire brush

Sandpaper or other sanding solution such as a sanding block

Acrylic spray paint

Degreaser

Enamel Sealant

Large drop cloth or dust sheet

Self-etching spray primer

Steps in brief

Clean the aluminium surface thoroughly

Sand the metal surface

Apply the primer then sand again

Apply the paint

Apply the Sealant

Each of these steps has guidelines and safety measures that should be adhered to.

Using angles for support

Aluminium angles are an L-shaped, extruded aluminium cross-section with inside radius corners and are more suited to structural and architectural applications.

Exceptionally versatile, aluminium angles are easy to fabricate, cut, weld, machine, polish, brush and indeed anodise and paint.

Most commonly applied for frames and supports, corner and edging protection and as an additional support frame.

Aluminium angles come with equal or unequal legs as specified for the task and can be finished in a number of different tempers, each of which play a different role.

The most common of these is the T6 temper which is first solution heat treated and then artificially aged.

Aluminium Angles in the commercial world

As a financial prospect aluminium is one of the most cost-effective elements available, and its broad interchangeability with other materials such as steel and many forms of plastic lend even more to these impressive credentials.

The above advantages alone mean a significant reduction in energy costs as well as a much greater ease of transportation.

Indeed since replacing steel as the everyday go-to metal, increased bulk orders of aluminium angles mean that every truck is carrying substantially less weight and reducing its environmental burden.

All these qualities have a positive effect not just on the world as a whole but also on the business's bottom line.

Throughout this article we have mentioned aluminium’s alloying potential, here are a few of the more common angle alloy grades.

Common aluminium grades used for angles

Typically, the preferred metals tend to be the 6000 series grades, predominantly 6063, 6061, 6082 and 6083.

Aluminium alloy 6063

Grade 6063 is known professionally as ‘architectural angle’ and with good reason.

Often finished in a T6 temper this robust metal presents with an extremely smooth surface texture, making it an ideal candidate for anodising.

When metal needs to be ‘attractive’ 6063 is a perfect solution, and common applications include window and door framing, furniture construction and of course, architectural surrounds and trim.

Aluminium alloy 6061

Also generally made in a T6 temper, grade 6061 has a few notable differences to 6063.

Significantly, grade 6061 is utilised with a more rounded inside corner but a sharp 90° outer corner with tapered structuring.

The standout properties of 6061 are its strength-to-weight ratio and it is this ease of movement and resilience that makes it ideal for more heavy-duty jobs involving marine equipment, train carriages, industrial piping networks and floor framing.

Aluminium alloy 6082

Alloy 6082 is probably the most prevalent of aluminium’s ‘angle metals’.

Its chemical composition is mainly manganese and silicon, with varying smaller amounts of magnesium, iron, copper, zinc, titanium and chromium added to the mix.

This composition has many of the benefits of alloy 6061 while also being stronger due to a higher level of manganese.

Aluminium alloy 6083

Last but by no means least, aluminium 6083 also has its own standout qualities. It is easy to machine with good tensile strength and reliable durability and having enhanced flexibility, resistance to temperature and excellent load-bearing characteristics, 6083 is well suited to high-stress applications.

What about wood?

In comparison to wood, aluminium angles are far cheaper, as well as being resistant to insects and without the same potential of cracking or warping over time.

Aluminium industry-specific application

Now we’ve had a look at the general uses of aluminium angles, let's take a more keyhole look at a couple of industry-specific uses.

Aluminium in the building industry

Becoming ever more popular, aluminium angles are becoming vastly known as a one size fits all solution, with their ease of application and lightweight nature, as well as a host of other properties including high levels of corrosion resistance, they can be applied to single-part jobs such as frame support, to multi-connecting applications like staircase railings and shop fittings.

Aluminium in the car industry

Aluminium angles can be found throughout today’s vehicles and can be placed into 2 categories, platform parts and component parts.

Platform parts are used where the vehicle body connects or closes, such as the doors, the boot, the bonnet, the chassis and the frame.

The component parts are the areas that aid in the operation of the vehicle, such as the powertrain, the heat management system, and the transmission, as well as the steering and braking systems.

With a positive drive towards reduced emissions and greener solutions, heavier and denser metals will over time be weeded out of the UK car industry and as this happens so aluminium is set to become more and more significant.

One of the greatest disadvantages stifling this migration is the electric car's ability to go long distances on a single charge.

While this capability remains so limited when compared to its diesel and petrol counterparts, any steel angle replaced in any car with an aluminium one goes a small step closer to lightening our carbon footprint, which is of course better for both pocket and planet, an automotive win-win.

Some lesser-known uses of aluminium angles

As described, the use of aluminium angles can be seen everywhere in today’s world, here is a brief selection of some of the less well-known places you may find this exceptionally versatile material.

Trapdoors and hatches

Cellars and basements can provide an ample storage area or even additional living space. A simple floor hatch can give easy access to this space, and whether used as a wine cellar, for added utility or even a panic room, aluminium angles create a reliable hinge and indeed have been recently used in one such instance in Plymouth for an outdoor gallery installation.

Outer chassis for computer towers

With today’s computers becoming ever more expensive, protecting them has never been so valuable.

Aluminium is a perfect material for angle support, thus ensuring a solid, dependable chassis and the utmost protection for the valuable components.

Using aluminium also gives your chassis a quality look and feel.

Water walls

Certainly an extravagance but definitely adding an extra punch to any installation, water walls offer a distinct framing option.

Aluminium angles allow the designer to create a water wall feature that is much less expensive than it looks, and if nothing else adds a thoughtful touch that is always an eye-catching talking point.

Shelving

Shelving solutions will never cease to have use, by using aluminium angles, shelves of all shapes and sizes can be easily and sturdily held, and with the precision of aluminium angles they can be made for highly specific areas such as designer corner shelving, or for use in areas that don’t see a lot of warmth.

As previously mentioned aluminium can also be painted and anodised so the design options are only limited by the imagination.

Frames for boats

Ask anyone in the street what boats are made from and many people's first answer would not be aluminium but its combination of corrosion resistance, lightweight nature and ease of fabrication make aluminium an ideal material for this purpose.

Whether you’re attempting to design an entirely new vessel, current boat building methods such as using widely spaced transverse frames or emphasising longitudinal stiffeners, aluminium allows for a whole range of imaginative yet dependable solutions.

Recycling

These days, recycling is a key factor when deciding on the best materials to use.

For this purpose aluminium has no equal, it can readily be melted down without losing any of its natural chemical properties and is therefore almost 100% recyclable.

Re-using aluminium is also exceptionally cost-effective and generates a fraction of the overall energy that other comparative metals may need.

In fact, much of the ‘new’ aluminium produced today is in fact metal that has been recycled multiple times, but still performs to exactly the same standard and creates the same aesthetic quality.