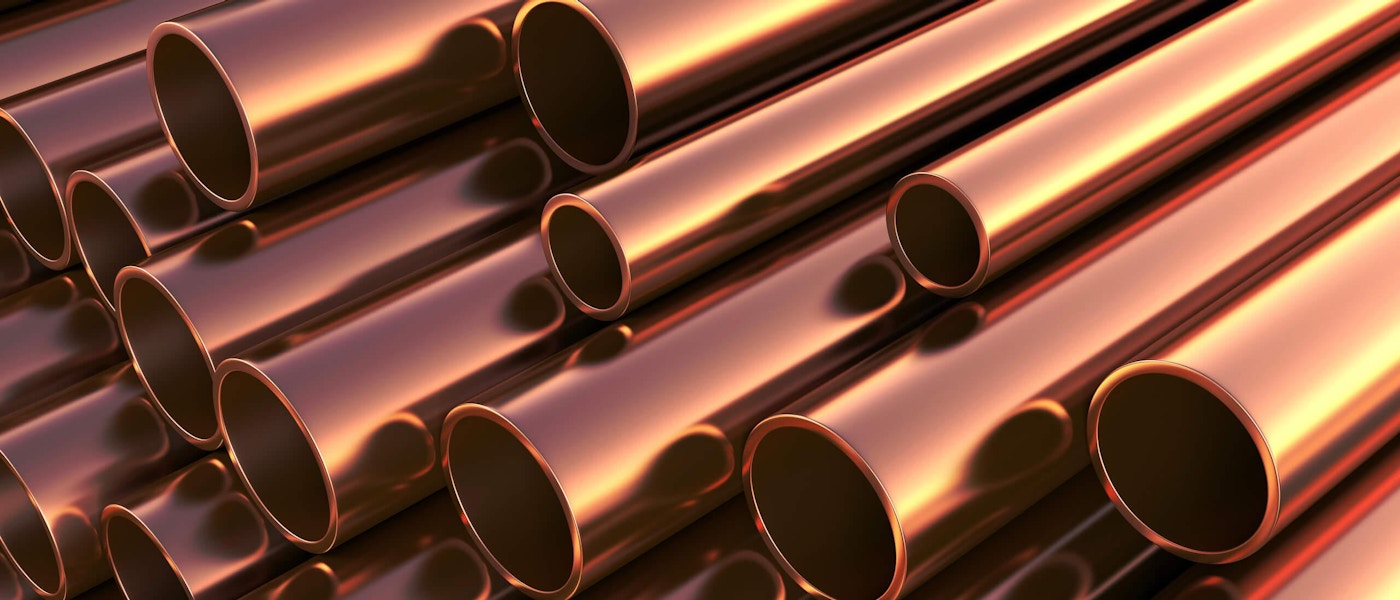

RoHS Copper & Copper Alloys

At Righton Blackburns we pride ourselves on our copper nickel range, known to be one of the most extensive in the UK and catering to a host of industries, we are a driving force in today's UK copper nickel market.

Your search did not match any items. Please ensure all words are spelled correctly or try different / more general keywords.

Copper Nickel has substantial advantages over many other metals, most notably throughout the marine industry. Benefits include superb resistance to seawater, brine water, salts and barnacles, among others, and for this reason is a go-to product in marine engineering, the oil and gas markets and shipbuilding.

Copper Nickel alloys possess superb corrosion resistance and as such are widely used for underwater piping systems and marine hardware. It is widely used in seawater systems, thermal desalination plants and in power generation applications.

Due to its excellent ductility, copper nickel alloys can be easily fabricated in a wide variety of fittings.

Copper nickel tubing can be readily worked into tube sheets for the manufacture of both shell and tube heat exchangers.

90/10 Cu-Ni tubing is also a significantly better choice for automotive brake tubing than low-carbon steel. It performs better for durability, safety and reliability and is also used widely in brake lines, fuel systems, and transmission units.

C70600, a 90/10 alloy, is common in the military, where heavy vehicles are needed, as well as in firefighting. This alloy has a high resistance to road salt corrosion and does not need a further protective coating.

Its use in brake tubing has massively increased in recent years as cars are built to last longer and the search for alternatives to expensive corrosion resistance coatings has intensified.

The 90-10 and 70-30 copper-nickel alloys were originally developed as an enhanced material for naval condensers and seawater piping over 60 years ago. Amazingly resilient to severe conditions, they are still used to this day by many of the world’s navies and commercial shipping companies.

Seawater itself is used as a coolant in tank cleaning, heating, waste disposal, ballast, fire-fighting and, through distillation as a source of freshwater for boiler feeds and sanitary water requirements.

Copper, when exposed to seawater, naturally forms a protective layer of oxide, protecting the material from degradation.

Copper-nickel has many benefits in today's changing world, notably that it can be 100% recycled, remelted and reused, making this exceptionally versatile and sustainable material even more viable for the energy conscious direction of many of today's industrial markets.

Copper nickel in its earliest commercial form was originally made around 300 B.C.

Referenced as ‘white copper’ in Chinese journals it involved the heated mix of copper, nickel and saltpetre.

Around 235 B.C. the first Greco-Bactrian copper-nickel coins came into use, starting a coinage trend that has lasted until this day.

In the US after the civil war ended copper-nickel was used by the U.S Mint to make three-cent and five-cent pieces. These coins had been previously made of silver which had become very scarce during the war.

In recent times the cladding and coating on American 50-cent pieces, quarters and dimes have been made of copper-nickel.

Euros are made with copper-nickel, as well as recent versions of the UK 20p and 50p coins.

Swiss Francs, South Korean Won, and the Jefferson Nickel all utilise their rust-free and durable properties.

Experienced multi-product specialists

In-house state of the art processing facilities

Large fleet of bespoke delivery vehicles

Value-added services provider

Standard, non-standard and customer-specific material

Opening Times

Experienced multi-product specialists

In-house state of the art processing facilities

Large fleet of bespoke delivery vehicles

Opening Times