Marine & Shipbuilding

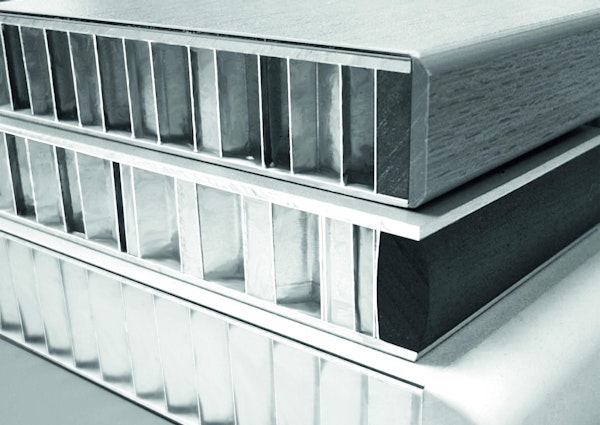

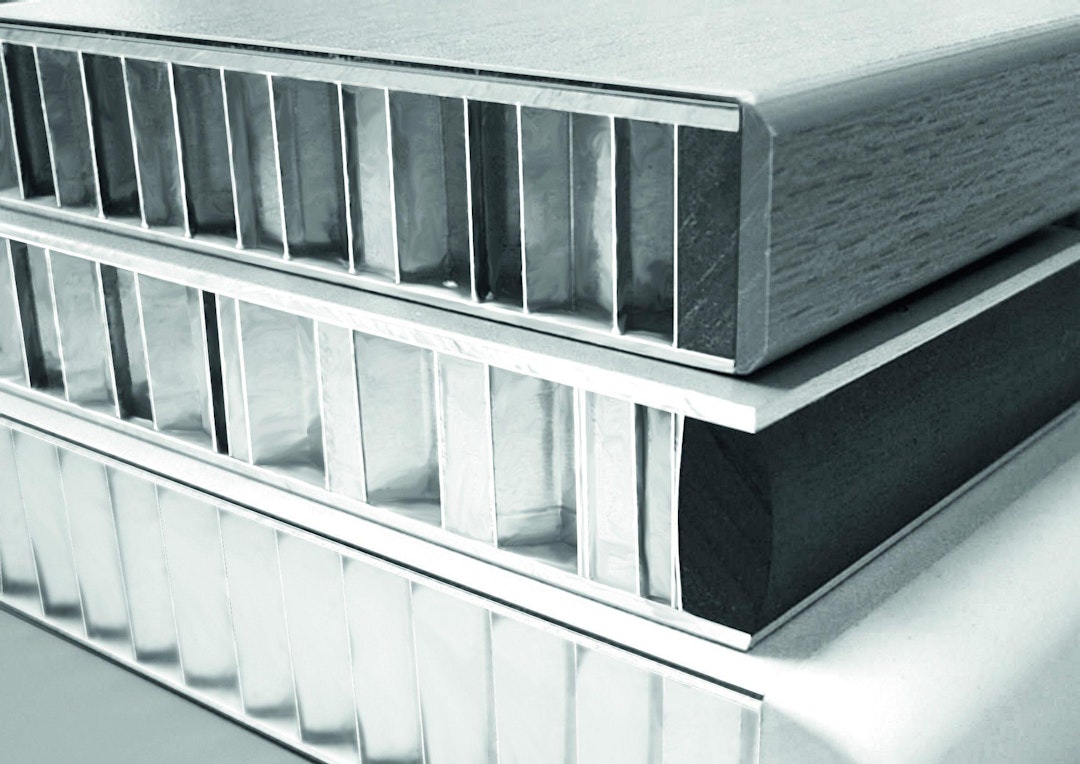

The system components, i.e. the “aluminium core” and the coil-coated “aluminium cover sheets” are bonded in a continuous process. The advantages are product quality and surface evenness; the material does not become brittle-hard but shows tough and resilient properties and an excellent peel strength. It is the ideal material for a host of applications in transport, architecture or industrial production.

| Sheet Size (mm) | Thicknesses (mm) |

|---|---|

2500 x 1250 | 5, 6, 10, 15 & 20 |

3000 x 1500 | 25 |

3050 x 1500 | 20 |

3125 x 1250 | 20 & 25 |

3125 x 1500 | 6, 10 & 15 |

6250 x 1250 | 6 & 20 |

6250 x 1500 | 10, 15 & 20 |

The honeycomb core consists of aluminium foils made of the alloy AlMn (EN AW 3003) Cell size is approx. 6.3 – 12.7 mm. The cover sheets of the honeycomb panels consist of corrosion-resistant Peraluman alloys (AlMg) and may be used in a decorative or functional manner, depending on the purpose of application.

| Dimension | Size |

|---|---|

Total Thickness | 5.5 - 50mm |

Length | 2000 - 9600mm |

Thickness of Aluminium Cover Sheet (Front) | 0.5/1.0mm |

Thickness of Aluminium Cover Sheet (Rear) | 0.5/1.0mm |

| Standard Thickness | Standard Width | Standard Length | Special Lengths (On Request) |

|---|---|---|---|

6, 10, 15, 20, 25mm | 1250mm, 1500mm | 2050mm, 2500mm, 3050mm, 5150mm, 6250mm | 1000mm to 13500mm |

| Type | Total Thickness (mm) | Aluminium Thickness (Front) | Aluminium Thickness (Rear) | Weight | Rigidity E-I | Section Modulus W |

|---|---|---|---|---|---|---|

06 | 6.0 | 1.0 | 0.5 | 4.8kg/m2 | 0.71kN/m2/m | 2.6cm3/m |

10 | 10.0 | 1.0 | 0.5 | 5.2kg/m2 | 2.19kN/m2/m | 4.6cm3/m |

15 | 15.0 | 1.0 | 1.0 | 6.9kg/m2 | 7.55kN/m2/m | 14.0cm3/m |

20 | 20.0 | 1.0 | 1.0 | 7.3kg/m2 | 13.90kN/m2/m | 19.0cm3/m |

25 | 25.0 | 1.0 | 1.0 | 7.7kg/m2 | 22.71kN/m2/m | 24.0cm3/m |

A complete range of aluminium honeycomb section are also available on request. Please contact your local Service Centre for further information.

Thickness: ± 0.2 mm (mill-finished/stove-lacquered)

Width: -0 / +4 mm

Lengths 2000 – 4000 mm: -0/+4 mm

Lengths 4001 – 9000 mm: -0/+6 mm

Approx -40 degrees C to +80 degrees C

In the shipbuilding industry, aluminium honeycomb panels plays an important role due to fire protection standards and the necessary weight reduction.

Thanks to its very light weight combined with its economic workability, the composite panel is used particularly in the interior of the ship for the ceilings, walls or furniture and in the outer area for balcony partitioning. In all the applications, the material offers optimum strength values at the same time.

Unique, mechanical properties, paired with excellent processing and aesthetic features make aluminium honeycomb panels the preferred material in facade cladding and roofing for planners, architects and designers.

With this decorative construction material with its even surface and high rigidity, innovative mounting systems for wall cladding and roofing can be implemented in a technically flawless manner.

Even applications with very demanding technical requirements, e.g. large self- supporting roofs or elements that are exposed to extremely high wind loads, can be constructed using aluminium honeycomb panels. In comparison with other materials, it has a high rigidity and an extremely low weight and offers decisive advantages due to the high tensile strength of the cover sheets.

Today’s strict economic and ecological conditions demand the implementation of sustainable structural materials in the field of transport that are lightweight, stable and fully recyclable.

In rail and transport vehicle construction, particularly the light weight and the high rigidity speak in favour of using aluminium honeycomb panels. Due to the lightweight construction, the CO2 emission can be significantly reduced and at the same time, there is less burden on the congested and restricted rail and road networks. It is recyclable, i.e. the panels are fed back into the material cycle and used for producing new material.

Honeycomb aluminium panels are excellently suited for special interior cladding, as well as for wall cladding and roofing in rail vehicle construction, for superstructures for lorries, for cabins, doors and flap systems.

Whether for cleanrooms, partitions, light-weight containers, cabins for machine tools, wind tunnels, lifting platforms, lifts, etc, aluminium honeycomb panels are the ideal material for industrial applications.

For example, using large-format, curtain wall honeycomb panels, it is possible to create an individual interior design in stairways and public areas, fast building systems in hat-profile construction can be implemented, or ground areas can be fitted with assembly systems for control rooms, navigating bridges and platforms. The honeycomb panels are also excellently suited as a carrier material for HPL, veneers, foils or paint.

Simple processing using commercially available tools on site and the possibility of a flexible adaptation of the modular dimension and fixation method offer the construction workers the greatest possible comfort.

Honeycomb panels can be processed using the following methods:

To avoid possible reflection differences (which does not apply to solid colours), we recommend installing the panels in the same direction as marked on the protective peel-off foil. Colour variations may occur between panels originating from different production batches. To ensure colour consistency, the total requirement for a project should be placed in one order.

Make sure to protect honeycomb panels against rain, any wetness penetrating the pallets and the formation of condensation. It is recommended to store a maximum of 6 pallets of identical size stacked on top of each other. Storage exceeding 6 months should be avoided, otherwise, it could be difficult to remove the protective foils. When stacking the panels, nothing should be placed in between them, as this could produce marks on the panels.

We recommend removing the protective foil as soon as possible after the installation. Due to UV radiation, it may occur that residual glue sticks to the surface of the panels. Do not mark the protective foils and panel surfaces with ink (markers), adhesive tape or labels. The solvents or softeners could damage the lacquered surface. Make sure to remove the protective foil as soon as possible after installation, as prolonged exposure to the elements could make the foil difficult to remove. The frequency of cleaning depends on the design and on the degree of soiling resulting therefrom.

During the life cycle of aluminium honeycomb panels, no substances containing CFC are set free at any time. Honeycomb panels can be fully recycled, i.e. the panels are fed back into the material cycle and used in the production of new material.

Please contact your local Righton Blackburns Service Centre for further information.

Experienced multi-product specialists

In-house state of the art processing facilities

Large fleet of bespoke delivery vehicles

Value-added services provider

Standard, non-standard and customer-specific material

Opening Times

Experienced multi-product specialists

In-house state of the art processing facilities

Large fleet of bespoke delivery vehicles

Opening Times